Leak Meters: technological innovation at the service of various industrial sectors

The industrial landscape is characterized by a growing demand for precision, safety and reliability in production processes. In this context, leak meters emerge as fundamental tools, playing an important role in the quality control and testing processes of products that must guarantee perfect watertightness.

Operation

Pressure decay leak meters work by measuring the Δp/Δt gradient, evaluating the change in pressure within a pressurized part over time. These tools are divided into:

- absolute systems, which directly measure internal pressure;

- differential systems, which compare the pressure variation between the piece being tested and a sample piece.

These instruments operate through four phases: filling or emptying the piece, pressure adjustment, measurement of pressure variation and discharge.

The second approach offers a higher level of precision and sensitivity to detect even the smallest leaks at high pressures, ensuring high standards of quality control.

There are also leak meters with direct flow measurement, i.e. very low flow meters, which in some particular applications can guarantee an advantage in terms of cycle time compared to pressure decay measurement.

Specific Applications

- Biomedical sector: in this category leak meters are irreplaceable tools for guaranteeing the safety and effectiveness of many devices. In hollow fiber dialyzers, for example, they are used to test the tightness of the body, heads and fibers. Their application in hemodialysis pumping units requires equally high precision in leak detection; their use is therefore essential to avoid risks for the patient due to blood contamination. Even more stringent requirements are required for the compliance of implantable pacemakers, for example.

- Appliances sector: in the production of detergent and rinse aid dispensers for dishwashers, pressure switches and water pumps for washing machines, leak meters play a key role in ensuring the tightness of these components. Their application in these contexts is essential to prevent unwanted detergent or water leaks and ensure the correct functioning of household appliances, helping to extend their life.

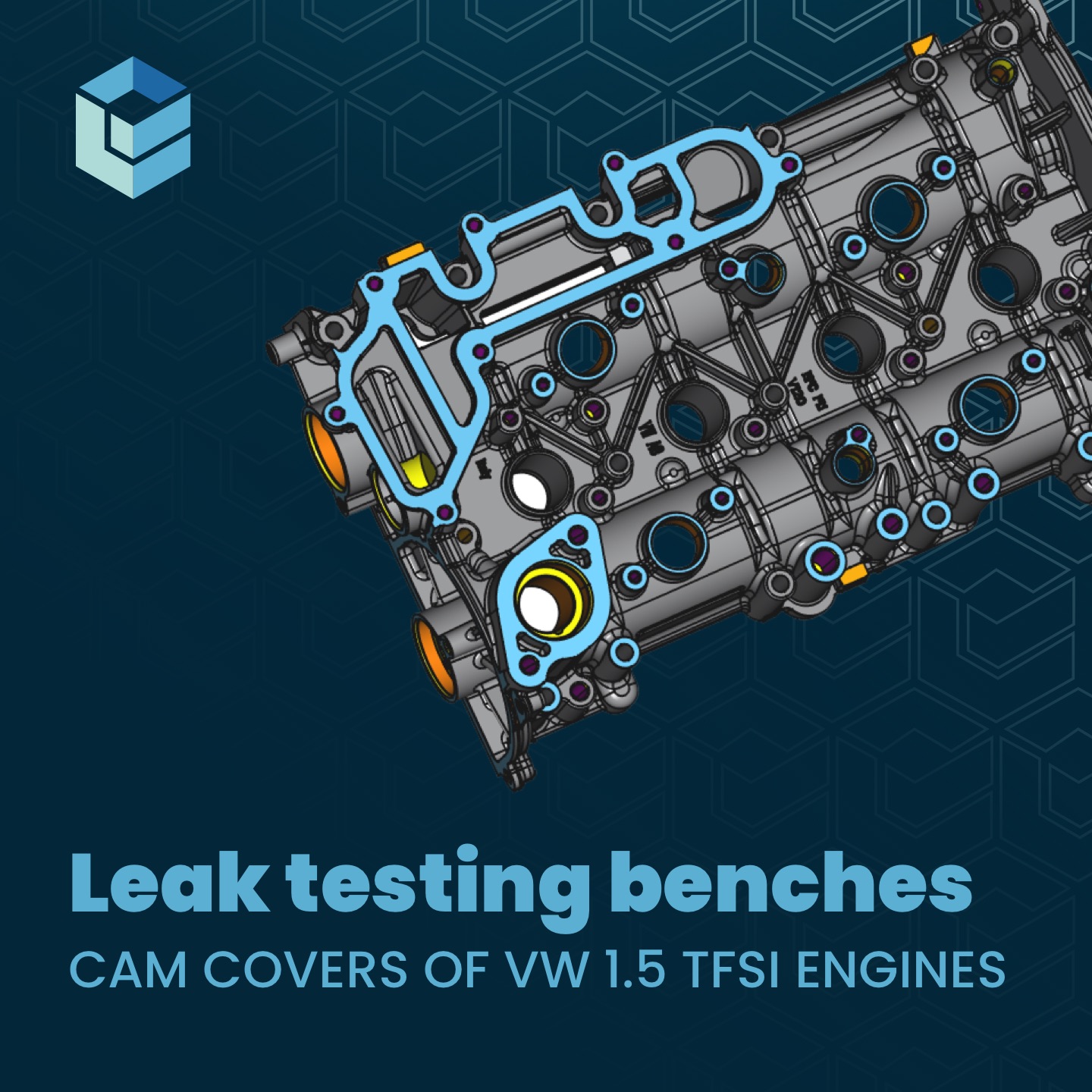

- Automotive sector: in this branch their use is wide and varied. From the fittings for the air conditioning system to the exhaust manifolds, passing through the lights and pressure sensors, hundreds of components installed on board vehicles must be subjected to leak tests to check that the gaskets, glues and welds are compliant and guarantee the air and water tightness required by vehicles that can be used in unfavorable environmental situations.

-

Industrial Sector: the application of leakage meters extends to the production of thousands of components such as shock absorbers, industrial filters, valves, etc. Their presence in leak testing processes helps to intercept critical non-conformities to ensure the safety and reliability of industrial supplies.

BLD and TLD Series Leak Meter

Our new BLD and TLD series offer leakage meters with integrated pneumatic circuit based on Δp/Δt measurement, proving to be the ideal choice for leak testing in many areas of industrial automation.

Some advantages introduced by these models:

- footprint reduced by up to 75% compared to previous versions;

- remote control via RS-232, Ethernet and USB;

- ultra-proven measurement methodology that ensures high precision, supported by a 24-month warranty;

- wide possibility of customization and availability of options to facilitate integration.

Technological Innovations and Future Developments

Continued innovation in leak meters promises to further improve their efficiency and accuracy. Advanced technologies, such as the integration of intelligent sensors and the use of algorithms that benefit from the know-how accumulated application after application, are making these tools increasingly sophisticated and suitable for rapidly evolving industrial needs.

We are developing new models of leak meters, to offer our integrator partners an increasingly high-performance product, with a competitive cost and highly customizable as in our DNA.

Would you like more information on the range of leak detectors? Contact us.