Leak testing benches with differential technology for the cam covers of VW 1.5 TFSI engines.

Every area of an internal combustion engine is exposed to the passage of lubricating oil, which ensures lubrication and cooling of the mechanical parts.

For this reason, each of these must meet a fundamental requirement: to prevent the formation of sweating and leaks caused by defective gaskets, porosity, or assembly errors.

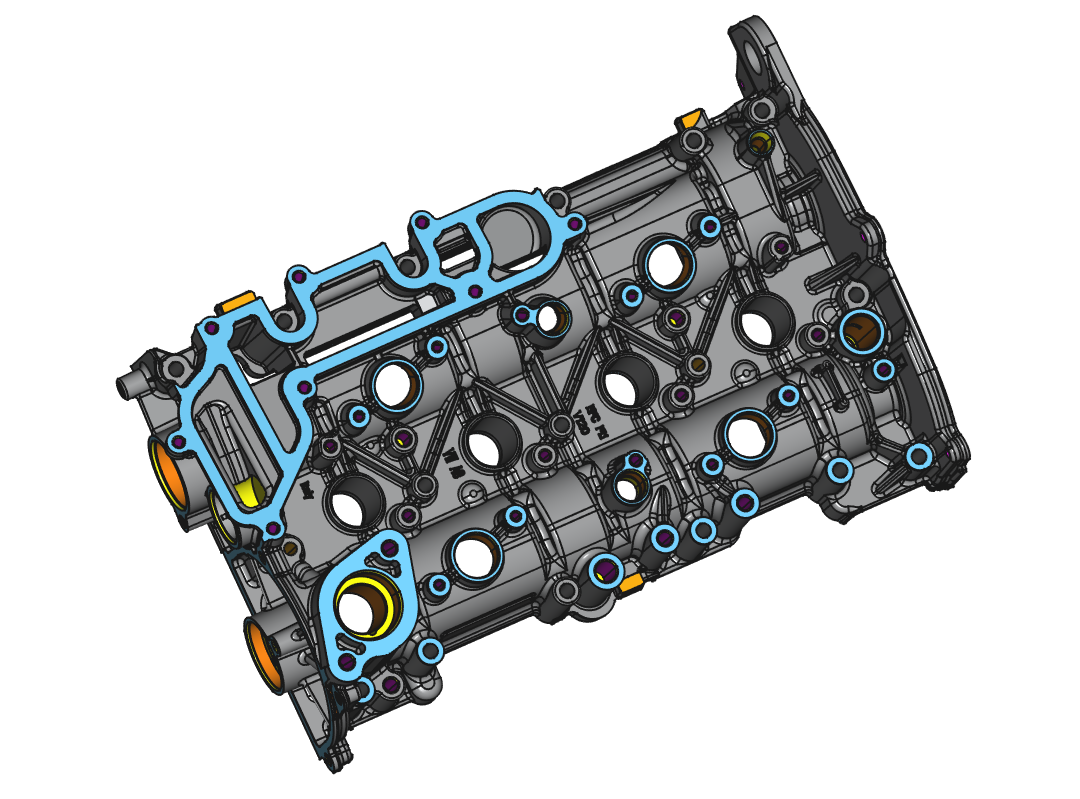

The cam cover, located at the top of the engine, is no exception.

The cam cover of the VW 1.5 TFSI engines

What is the cam cover made of?

The cam cover of the VW 1.5 TFSI engines features:

- Camshafts that control the intake and exhaust valves;

- Variable valve timing control actuators;

- An aluminum alloy die-cast piece, subsequently machined on CNC centers, subjected to various optical and leak tests to detect manufacturing defects and assess the absence of porosity.

How E.C.B. works for the casing and oil channel leak testing system

Overview of the robotic leak testing cell

To meet a request for increased production of this type of engine, the cam cover supplier once again turned to E.C.B. for the construction of the test benches required for the new production line.

Our approach

Two dual-station benches, operated by an anthropomorphic robot, were designed, manufactured, and installed.

Each leak testing bench is divided into two stations:

- one for the low-pressure leak testing of the casing

- one for the high-pressure leak testing of the oil channels

Ten independent zones are tested in parallel and completely asynchronously, at variable and programmable pressures.

What instrumentation was used?

The leak testing instrumentation again opted for the DLD differential system with remote modules, which features 10 independent channels.

The proprietary E.C.B. software was installed on the machine's PC, centralizing its management.

The operator can control both the automation and the measuring instruments from a single touchscreen panel, with process traceability and remote assistance.

Each leak testing bench allows for parallel testing of two parts with a cycle time of less than 60 seconds.

Low-pressure casing leak testing station

High-pressure oil channel leak testing station

Proprietary management software for the DLD system with remote modules

Differential leak testing modules: high performance “tailor-made”

The new DLD differential leak testing modules were used on the test stations, offering a series of particularly interesting features for battery applications:

- Modular architecture: module connections are minimized, and the E.C.B. software can independently and asynchronously manage a variable number of modules, virtually without limits.

- High resolution even at high test pressures: the standard pressure ranges available reach 12 bar, but even when they are increased to 30 bar in special versions, a resolution of 0.01 mbar is guaranteed, which is impossible to achieve with standard gauge pressure transducers.

- Electronic pressure regulation: the module automatically and autonomously manages test pressure regulation.

- Self-test circuit with reference leak: the valve group integrates the solenoid valve and the output fittings for connecting a calibrated reference leak, allowing for periodic self-test cycles.

- Very competitive cost: our modular architecture allows, as the number of test stations increases, manage them in parallel, resulting in even greater savings compared to using stand-alone, single-channel leak meters.

Would you like more information about an automatic leak testing station? Contact us.